Precision sheet metal processing technology

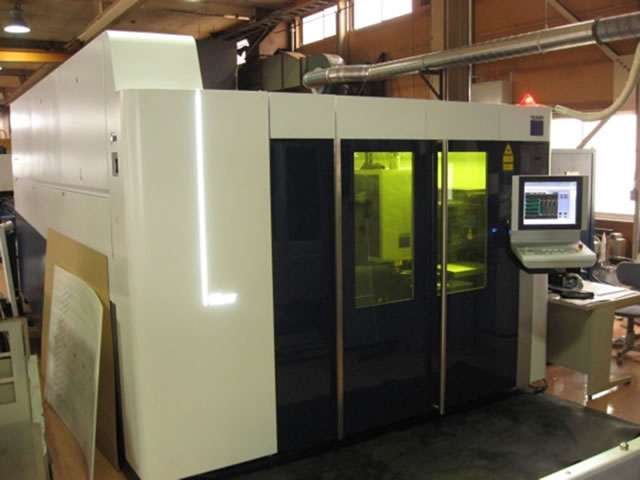

Laser processing

Being the first to introduce laser processing machines in Niigata Prefecture, we have always tried to stay one step ahead of the competition in terms of laser processing.

Recently, we have introduced the TruLaser 5030 fiber laser machine (TRUMPF) to more quickly respond to customer requests.

We are also capable of 3Dmachining.

Recently, we have introduced the TruLaser 5030 fiber laser machine (TRUMPF) to more quickly respond to customer requests.

We are also capable of 3Dmachining.

Pipe laser processing

Compared to conventional machining methods, this method reduces man-hours and machining costs.

It allows machining into free designs, including complicated shapes.

It allows machining into free designs, including complicated shapes.

Fiber laser machining

Equipped with a 5 kW disk laser oscillator, this machine is capable of machining a variety of nonferrous metals, such as stainless steel, aluminum, copper and brass, which has been difficult with the conventional CO2 laser machining.

In combination with a linear drive, it can machine thin plates at high speeds.

In combination with a linear drive, it can machine thin plates at high speeds.

Machining by machine tool

Because of the introduction of a new machining center in 2009, the efficiency of machining by machine tools has been greatly increased.

In addition, we have come to respond to a wide variety of machining needs and short delivery periods.

In addition, we have come to respond to a wide variety of machining needs and short delivery periods.

Bending/roll machining

In terms of bending machining, because of the combination of press brakes of various sizes and a multi-bender (Salvagnini) capable of more complicated machining, we have significantly widened the range of workpieces we can machine.

We are making daily efforts toward structures free of welding at the design and development stage.

We are making daily efforts toward structures free of welding at the design and development stage.

Welding

By means of TIG welding, MAG welding, YAG welding, and arc welding, we are capable of welding three-dimensional objects, ranging from thin to thick (frames of housings, pedestals, square pipes and round pipes).

Fiber laser welding

Through fiber laser welding, welding of higher quality with less distortion compared to other welding methods is possible. Please rely on us for welding difficult-to-weld materials.

Because of a robot-mounted system having a 1.5 m travel cart, we can respond to a variety of welding needs ranging from small to large objects, ranging from multi-type, small-quantity production to mass production.

Because of a robot-mounted system having a 1.5 m travel cart, we can respond to a variety of welding needs ranging from small to large objects, ranging from multi-type, small-quantity production to mass production.

Finishing/assembly

This process consists of work by the finishing/painting section and the assembly section.

The finishing/painting section conducts the finishing and painting of sheet metal.

The assembly section assembles the machine, device or equipment, and also carries out installation, testing and maintenance.

It can also conduct wiring work, piping work and duct construction.

The finishing/painting section conducts the finishing and painting of sheet metal.

The assembly section assembles the machine, device or equipment, and also carries out installation, testing and maintenance.

It can also conduct wiring work, piping work and duct construction.